underwater dredge pump factory

Latest articles

The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read MoreMechanical Seals

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read MoreSlurry pump design

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read MoreThe concentration of solids in the slurry - measured as a percentage of the total volume.

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read MoreIn AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read MoreCorrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read MoreStep 3

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read More3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read MoreAny type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read More- Pumping media where abrasive particles are present

underwater dredge pump factory...

underwater dredge pump factory 【underwater dredge pump factory】

Read More

Popular articles

- Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

- 1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

- Slurry Pump

- Ideal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

- Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal , slurry pump, . Lets talk about how slurry pumps differ from standard pumps and how to narrow your choices.

- Slurry Pump Impeller Size

Latest articles

-

- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

-

First, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

-

- Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

-

Aier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

-

The Difference Between Flushing And Quenching in Slurry Pump Seals

-

- Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

Links

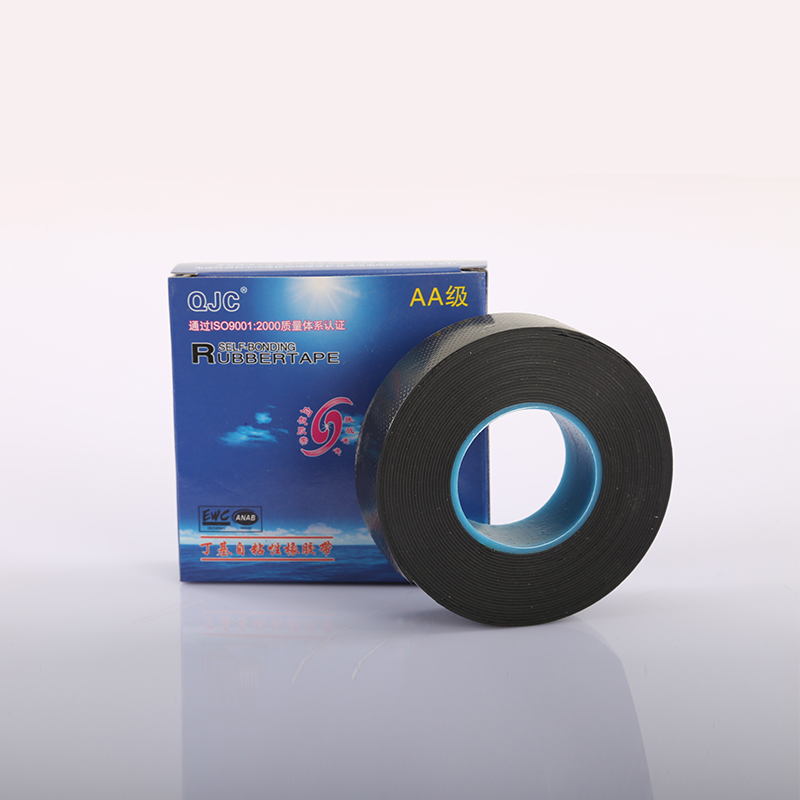

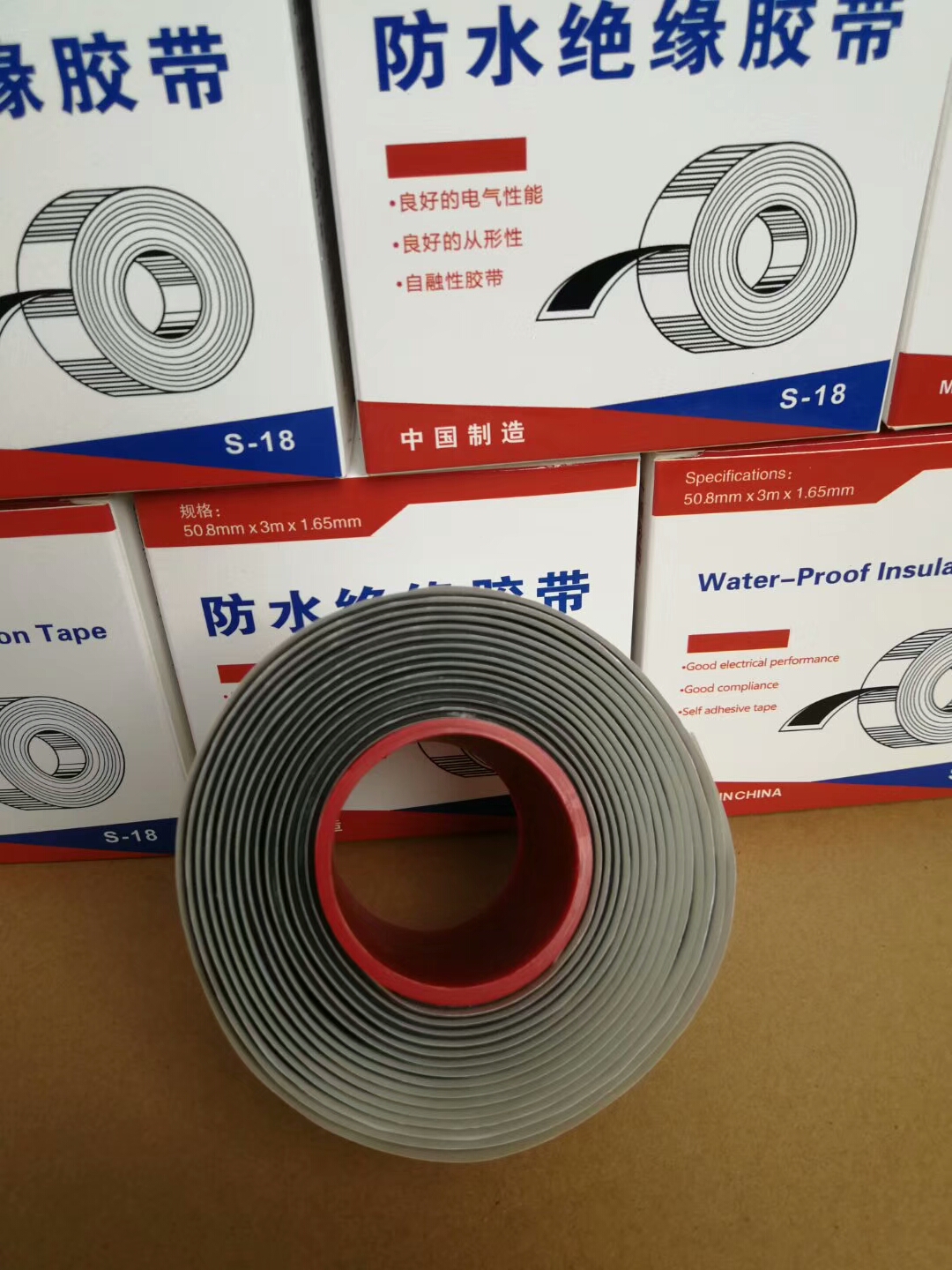

- In conclusion, rubber tape self-fusing is a must-have tool for anyone involved in DIY projects or home improvement. Its unique combination of properties, including its self-fusing abilities, high tear strength, and versatility, make it an invaluable asset in a variety of situations. Whether you're a professional contractor or a DIY enthusiast, rubber tape self-fusing is sure to become a staple in your toolkit.

- In the vast expanse of industrial materials, high-temperature insulation tape stands out as a critical component, ensuring safety and efficiency in various applications. This tape, designed to withstand extreme temperatures, is a testament to human innovation and adaptability. Its significance transcends mere physical properties, reflecting our relentless pursuit of solutions that push boundaries and redefine what we once thought possible.

In conclusion, a door bottom seal rubber strip is a practical and efficient solution for improving the insulation and weatherproofing of your doors. By creating a barrier against drafts, moisture, and dust, these strips can help to enhance the energy efficiency and comfort of your home. Invest in a high-quality rubber strip today and enjoy the benefits of a well-insulated and protected living space.

Selecting the Right Control Box for Your Needs

What is Black PVC Electrical Tape?

Why You Would Use A Self-Fusing Electrical Tape

Repairing split garden hose pipes

strip seal. These seals are used in hydraulic systems, fuel tanks, and other components to prevent leaks and ensure the safety and performance of the aircraft. Strip seals in aerospace applications must meet stringent requirements for temperature resistance, pressure tolerance, and compatibility with various fluids.

butyl weather stripping. It can be installed using various methods such as gluing, nailing, or even just pressing it into place for a pressure fit. This flexibility in application further adds to its appeal, making it suitable for both professional contractors and DIY enthusiasts.

butyl weather stripping. It can be installed using various methods such as gluing, nailing, or even just pressing it into place for a pressure fit. This flexibility in application further adds to its appeal, making it suitable for both professional contractors and DIY enthusiasts.Seal out moisture from electrical connections

Control boxes are primarily employed to regulate electricity flow in electrical components. This means they playan essential role in safeguarding your devices. They are however multipurpose interfaces capable of fulfilling numerous roles.